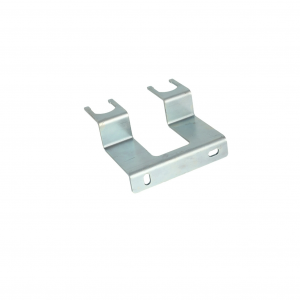

Izingxenye Ze-Aluminium Ezenziwe Ngokwezifiso Izingxenye Ezigxiviziwe

Incazelo

| Uhlobo Lomkhiqizo | umkhiqizo ngokwezifiso | |||||||||||

| Isevisi ye-One-Stop | Ukuthuthukiswa kwesikhunta kanye nomklamo-hambisa amasampuli-inqwaba yokukhiqiza-ukuhlola-ukwelashwa-ukupakisha-ukulethwa. | |||||||||||

| Inqubo | ukunyathela, ukugoba, ukudweba okujulile, ukwakhiwa kwensimbi yeshidi, ukushisela, ukusika i-laser njll. | |||||||||||

| Izinto zokwakha | carbon steel, insimbi engagqwali, i-aluminium, ithusi, insimbi yashukumisa njll. | |||||||||||

| Ubukhulu | ngokuya ngemidwebo yekhasimende noma amasampula. | |||||||||||

| Qeda | Futha umdwebo, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njll. | |||||||||||

| Indawo Yesicelo | Izingxenye zezimoto, izingxenye zemishini yezolimo, izingxenye zemishini yobunjiniyela, izingxenye zobunjiniyela bokwakha, izesekeli zengadi, izingxenye zemishini ezivumelana nemvelo, izingxenye zomkhumbi, izingxenye zezindiza, ukufakwa kwamapayipi, izingxenye zamathuluzi ehadiwe, izingxenye zamathoyizi, izingxenye ze-elekthronikhi, njll. | |||||||||||

Izinhlobo zokugxiviza

Sinikezela ngesiteji esisodwa nesiningi, i-progressive die, i-deep draw, i-fourslide, nezinye izindlela zokugxiviza ukuze uqinisekise indlela ephumelela kakhulu yokukhiqiza imikhiqizo yakho. Ochwepheshe be-Xinzhe bangafanisa iphrojekthi yakho nesigxivizo esifanele ngokubuyekeza imodeli yakho ye-3D elayishiwe kanye nemidwebo yobuchwepheshe.

- I-Progressive Die Stamping isebenzisa ama-dies amaningi nezinyathelo ukudala izingxenye ezijulile kunalokho obekungafinyelelwa kuzo ngokufa okukodwa. Iphinde inike amandla amajiyometri amaningi ingxenye ngayinye njengoba edlula ekufa okuhlukahlukene. Le nqubo ifaneleka kakhulu umthamo ophezulu kanye nezingxenye ezinkulu njengalezo ezisembonini yezimoto. I-Transfer die stamping iyinqubo efanayo, ngaphandle kokuthi isitembu sefa esiqhubekayo sihlanganisa ucezu lokusebenza olunamathiselwe emgqeni wensimbi odonswe kuyo yonke inqubo. I-Transfer die stamping isusa ucezu lokusebenza futhi iluhambise eduze kwe-conveyor.

- I-Deep Draw Stamping idala izitembu ezinemigodi ejulile, njengonxande abavalelwe. Le nqubo idala izingcezu eziqinile kusukela ukuwohloka okwedlulele kwensimbi kucindezela isakhiwo sayo sibe ifomu elicwebezelayo. Ukugxiviza okujwayelekile kokudweba, okubandakanya ukufa okungajulile okusetshenziselwa ukubumba insimbi, nakho kuvame ukusetshenziswa.

- I-Fourslide Stamping ibumba izingxenye ukusuka kuzimbazo ezine esikhundleni sokusuka ohlangothini olulodwa. Le ndlela isetshenziselwa ukwakha izingxenye ezincane eziyinkimbinkimbi ezihlanganisa izingxenye ze-electronics njengezixhumi zebhethri yefoni. Inikeza ukuguquguquka okwengeziwe kwedizayini, izindleko eziphansi zokukhiqiza, kanye nezikhathi zokukhiqiza ezisheshayo, isitembu se-fourslide sidumile ezimbonini ze-aerospace, zezokwelapha, zezimoto, nezikagesi.

- I-Hydroforming iyinguquko yokugxiviza. Amashidi abekwe phezu kwedayizi enomumo ophansi, kuyilapho ukwakheka okungaphezulu kuyisinye sikawoyela esigcwala ukucindezela okuphezulu, ukucindezela insimbi ibe sesimweni sefa elingezansi. Izingxenye eziningi zingakhiwa nge-hydroform ngesikhathi esisodwa. I-Hydroforming iyindlela esheshayo nenembayo, nakuba idinga ukusika izingxenye zeshidi ngemva kwalokho.

- Ukuvala kusika izingcezu eshidini njengesinyathelo sokuqala ngaphambi kokwenza. I-Fineblanking, inguquko yokungasho lutho, yenza ukusikeka okunembile ngemiphetho ebushelelezi kanye nendawo eyisicaba.

- I-Coining ingolunye uhlobo lokuvala okudala ama-workpieces amancane ayindilinga. Njengoba kuhilela amandla abalulekile ukwakha ucezu oluncane, kwenza insimbi ibe lukhuni futhi isuse ama-burrs namachopho amaholo.

- Ukushaya ngesibhakela kuphambene nokuvala; kuhilela ukususa impahla ku-workpiece esikhundleni sokususa izinto ukuze udale i-workpiece.

- I-embossing idala idizayini enezinhlangothi ezintathu ensimbi, ephakanyiswe ngaphezu kwendawo noma ngochungechunge lwezingcindezi.

- Ukugoba kwenzeka ku-eksisi eyodwa futhi kuvame ukusetshenziselwa ukwakha amaphrofayili ngomumo ongu-U, V, noma u-L. Le nqubo yenziwa ngokugoqa uhlangothi olulodwa bese ugoba olunye phezu kwedayizi noma ngokucindezela insimbi ibe yifa noma imelene nayo. I-Flanging igobela amathebhu noma izingxenye zocezu lokusebenza esikhundleni sayo yonke ingxenye.

Ukuphathwa kwekhwalithi

Ithuluzi lokuqina likaVickers.

Ithuluzi lokulinganisa iphrofayela.

Insimbi ye-Spectrograph.

Ithuluzi lokuxhumanisa ezintathu.

Isithombe Sokuthunyelwa

Inqubo Yokukhiqiza

01. Isikhunta design

02. Ukucutshungulwa Kwesikhunta

03. Ukucubungula ucingo

04. Ukwelashwa kokushisa kwesikhunta

05. Ukuhlanganiswa kwesikhunta

06. Ukulungisa iphutha lesikhunta

07. Ukukhipha imali

08. i-electroplating

09. Ukuhlolwa Komkhiqizo

10. Iphakheji

Inqubo Yokugxiviza

Inqubo yokwelashwa kwendawoizingxenye ze-aluminium stamping:

Embonini yokugxiviza, izingxenye ze-aluminium stamping nazo ziyingxenye evamile kakhulu yokugxiviza kwensimbi. Izindlela ezijwayelekile zokwelashwa kwezingxenye ze-aluminium stamping yilezi:

1.Anodizing

I-anodizing ingenza ngempumelelo ukuntuleka kokuqina kwendawo kanye nokumelana nokugqoka kwezingxenye zokugxiviza ze-aluminium. Kungase futhi kukhulise kakhulu isikhathi sokusebenzisa izingxenye ze-aluminium stamping futhi wenze umkhiqizo ubukeke muhle kakhulu. Namuhla, i-anodizing isiphenduke indlela yokwelapha engaphezulu esetshenziswa kakhulu emikhiqizweni yokugxiviza isitembu se-aluminium. I-anodizing ibhekisela ku-electrochemical oxidation yezinsimbi noma ama-alloys. I-Aluminium nama-alloys ayo yakha ifilimu ye-oxide emkhiqizweni we-aluminium (i-anode) ngenxa yomphumela wamanje kagesi osetshenziswa ku-electrolyte ehambisanayo nezimo ezithile zenqubo.

2.Ukuqhunyiswa kwesihlabathi

I-Sandblasting ngokuvamile iyinqubo ephakathi nendawo yokwelashwa kwezingxenye zokugxiviza ze-aluminium. Ngemuva kokuthi izingxenye zokugxiviza ze-aluminium zifakwe isihlabathi, ama-surface burrs namabala kawoyela angasuswa ngempumelelo. Ingathuthukisa ukuhlanzeka kwendawo yezingxenye ze-aluminium stamping. Ngokulawula izinto eziqhumayo, izindawo ezihlukene zingatholakala futhi ukushuba komkhiqizo kungandiswa. Ukusebenza komkhiqizo kungathuthukiswa kakhulu. Enqubweni elandelayo yokwelashwa kwendawo, ukunamathela phakathi kwezingxenye ze-aluminium stamping kanye nokwemboza nakho kungandiswa kakhulu, okwenza umkhiqizo uhlale isikhathi eside futhi muhle.

3. Ukwelashwa kokupholisha

Izingxenye zokunyathela ze-aluminium epholishiwe zingasondela kumphumela wesibuko, okuthuthukisa kakhulu izinga kanye nobuhle bomkhiqizo. Kodwa-ke, ngenxa yezimpawu zemikhiqizo ye-aluminium, izitembu ze-aluminium zidinga ukupholisha okuncane. Uma kungekho okunye ukwelashwa okungaphezulu okwenziwa ngemva kokupholishwa, ukuqina komkhiqizo kuzothinteka. Ngaphezu kwalokho, ngemva kokupholishwa kwezingxenye ze-aluminium stamping, kunzima ukugcina umphumela wesibuko isikhathi eside. Ngakho-ke, uma umphumela wesibuko udingeka, kunconywa ukusebenzisainsimbi engagqwalinjengempahla yomkhiqizo.

4. Ukucubungula ngocingo

Kunezinhlobo eziningi zezitembu ze-aluminium ezixutshwe, ezivame kakhulu ukudweba okuqondile, ukudweba okunesiphithiphithi, umdwebo ovunguzayo kanye nokudweba intambo. Ngemva kokuba izingxenye zokugxiviza ze-aluminium sezidonswe ngocingo, izimpawu ezicacile nezithambile zingabonakala ngaphandle, futhi umkhiqizo unikeza abantu isipiliyoni esibonakalayo samaphethini kasilika akhanyayo.

Izingxenye zokugxiviza ze-Aluminium ngokuyisisekelo zidinga ukwelashwa okungaphezulu ngemuva kokucubungula, kodwa iyiphi indlela yokwelapha ekhethwayo incike ezidingweni ezithile zekhasimende. Uma singekho isicelo sekhasimende, i-anodizing ivamise ukuba yinto emisiwe.

Kungani ukhetha i-Xinzhe yezingxenye zokunyathela zensimbi ngokwezifiso?

U-Xinzhe uchwepheshe wokugxiviza izitembu zensimbi omvakashelayo. Ukusebenzela amaklayenti emhlabeni wonke, sesisebenze ngokukhethekile ekugxivizeni ngensimbi cishe iminyaka eyishumi. Ochwepheshe bethu besikhunta abanekhono eliyingqayizivele nonjiniyela bokuklama bazinikele, bangochwepheshe, futhi banenkambo yokusebenza eqinile.

Siyini isihluthulelo sezimpumelelo zethu? Itemu elilodwa lifingqa impendulo: ukuqinisekiswa kwekhwalithi kanye nemininingwane. Kithina, iphrojekthi ngayinye ihlukile. Siqhutshwa umbono wakho, futhi kuwumsebenzi wethu ukufeza lowo mbono. Sizama ukuqonda yonke ingxenye yephrojekthi yakho ukuze sifeze lokhu.

Senza umzamo omkhulu ukuze sifeze umbono wakho uma sesiwubambile. Endleleni, kunezindawo zokuhlola eziningana. Lokhu kusenza siqinisekise ukuthi umkhiqizo oqediwe uzanelisa ngokugcwele izidingo zakho.

Iqembu lethu njengamanje ligxile ekuhlinzekeni ngezinsizakalo zesitembu sensimbi ngokwezifiso kule mikhakha elandelayo:

Ukunyathela ngezigaba kokubili ngamanani amancane namakhulu

Ukunyathela okwesibili ngamaqoqo amancane

ukushaya ngaphakathi kwesikhunta

Ukuthepha okwesibili noma ukuhlanganisa

Ukukhanda nokubumba

Uma ungathanda ulwazi olwengeziwe, ungangabazi ukuxhumana nathi.