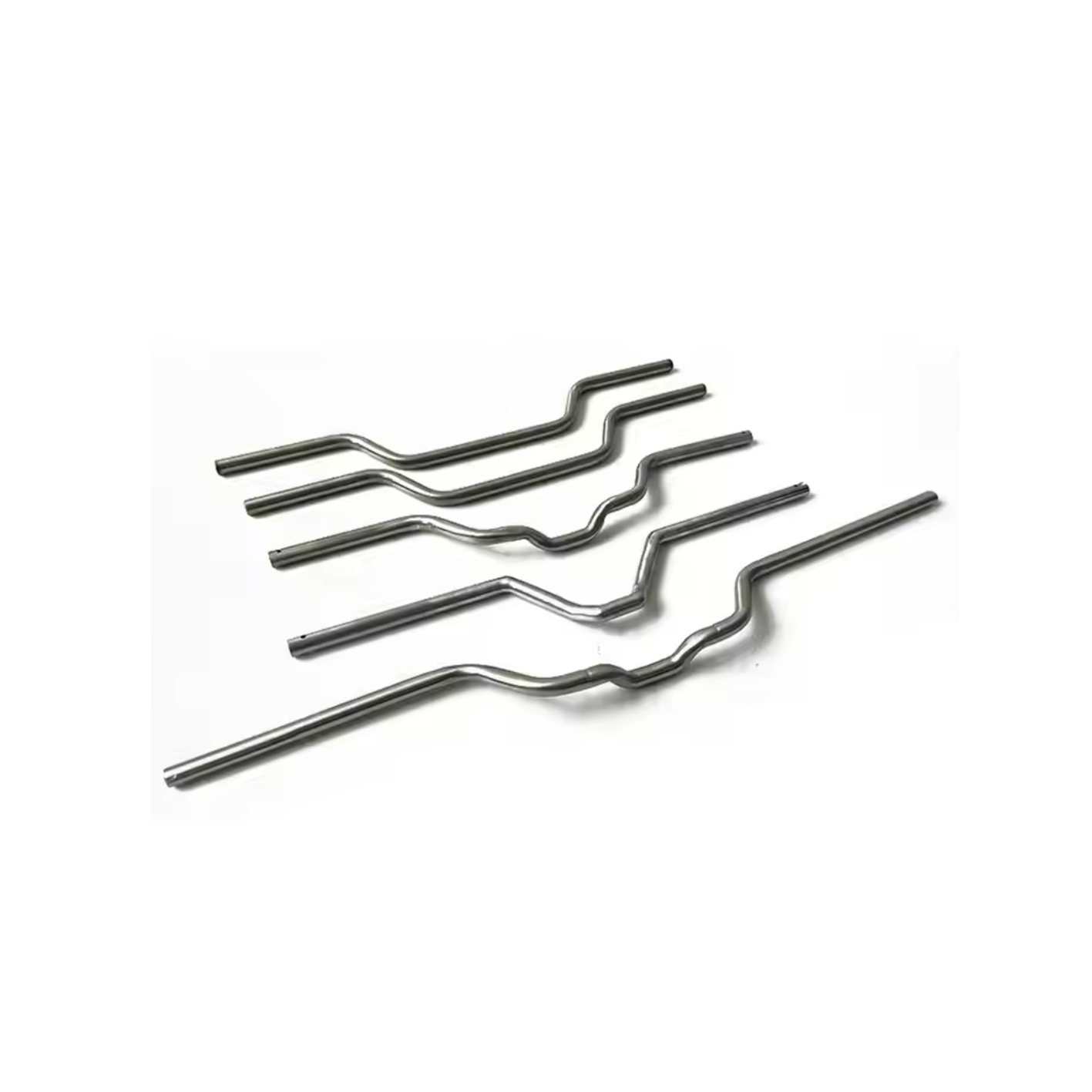

Ukukhiqizwa okwenziwe ngokwezifiso kwezingxenye zokugoqa zepayipi lensimbi engagqwali

Incazelo

| Uhlobo Lomkhiqizo | umkhiqizo ngokwezifiso | |||||||||||

| Isevisi ye-One-Stop | Ukuthuthukiswa kwesikhunta kanye nomklamo-hambisa amasampuli-inqwaba yokukhiqiza-ukuhlola-ukwelashwa-ukupakisha-ukulethwa. | |||||||||||

| Inqubo | ukunyathela, ukugoba, ukudweba okujulile, ukwakhiwa kwensimbi yeshidi, ukushisela, ukusika i-laser njll. | |||||||||||

| Izinto zokwakha | carbon steel, insimbi engagqwali, i-aluminium, ithusi, insimbi yashukumisa njll. | |||||||||||

| Ubukhulu | ngokuya ngemidwebo yekhasimende noma amasampula. | |||||||||||

| Qeda | Futha umdwebo, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njll. | |||||||||||

| Indawo Yesicelo | Izingxenye zezimoto, izingxenye zemishini yezolimo, izingxenye zemishini yobunjiniyela, izingxenye zobunjiniyela bokwakha, izesekeli zengadi, izingxenye zemishini ezivumelana nemvelo, izingxenye zomkhumbi, izingxenye zezindiza, ukufakwa kwamapayipi, izingxenye zamathuluzi ehadiwe, izingxenye zamathoyizi, izingxenye ze-elekthronikhi, njll. | |||||||||||

Izinzuzo

1. Ngaphezu kweminyaka eyi-10yobungcweti bokuhwebelana phesheya kwezilwandle.

2. Nikezaisevisi eyodwa-stopkusukela ekwakhiweni kwesikhunta kuya ekulethweni komkhiqizo.

3. Isikhathi sokulethwa okusheshayo, cisheIzinsuku ezingama-30-40. Isitoko lingakapheli iviki elilodwa.

4. Ukuphathwa kwekhwalithi okuqinile kanye nokulawulwa kwenqubo (ISOUmkhiqizi oqinisekisiwe kanye nemboni).

5. Amanani anengqondo ngaphezulu.

6. Professional, imboni yethu ineezingaphezu kuka-10iminyaka yomlando emkhakheni wensimbi yokugxiviza ishidi lensimbi.

Ukuphathwa kwekhwalithi

Ithuluzi lokuqina likaVickers.

Ithuluzi lokulinganisa iphrofayela.

Insimbi ye-Spectrograph.

Ithuluzi lokuxhumanisa ezintathu.

Isithombe Sokuthunyelwa

Inqubo Yokukhiqiza

01. Isikhunta design

02. Ukucutshungulwa Kwesikhunta

03. Ukucubungula ucingo

04. Ukwelashwa kokushisa kwesikhunta

05. Ukuhlanganiswa kwesikhunta

06. Ukulungisa iphutha lesikhunta

07. Ukukhipha imali

08. i-electroplating

09. Ukuhlolwa Komkhiqizo

10. Iphakheji

Metal stamping industry

Ngobubanzi bezinhlelo zokusebenza nemikhakha, sinikezela ngezinsizakalo zokugxiviza zensimbi. Imikhakha yezimoto, i-aerospace, kanye nezokwelapha izimboni ezimbalwa nje esizihlinzekayo ngezigxivizo zensimbi.

imoto I-Metal Stamping: Kusukela ku-chassis kuya kumaphaneli eminyango kuya kumabhande ebhande lesihlalo, isitembu sensimbi sisetshenziswa ukwenza amakhulu ezingxenye zezimoto ezahlukahlukene.

I-Aerospace Metal Stamping: Phakathi kwezinqubo ezibaluleke kakhulu emkhakheni we-aerospace, isitembu sensimbi sisetshenziswa ukwenza izinhlobonhlobo zezingxenye zezinhlelo ze-aerospace.

Ukugxiviza kwensimbi okunembayo kungasetshenziswa embonini yezokwelapha ukukhiqiza izingxenye nezingxenye ezihlangabezana nekhwalithi edingekayo kanye namazinga okubekezelelana.

INKONZO YETHU

1. Ithimba lochwepheshe be-R&D - Onjiniyela bethu bahlinzeka ngemiklamo ehlukile yemikhiqizo yakho ukuze isekele ibhizinisi lakho.

2. Ithimba Lokuqondisa Ikhwalithi - Yonke imikhiqizo ihlolwa ngokuqinile ngaphambi kokuthunyelwa ukuze kuqinisekiswe ukuthi yonke imikhiqizo isebenza kahle.

3. Ithimba lezokuthutha elisebenzayo - ukupakishwa okwenziwe ngokwezifiso kanye nokulandelela okufika ngesikhathi kuqinisekisa ukuphepha uze uthole umkhiqizo.

4. Ithimba elizimele langemuva kokuthengisa elihlinzeka ngezinsizakalo ezisebenzayo ngesikhathi kumakhasimende amahora angama-24 ngosuku.

5. Ithimba labadayisi abangochwepheshe - ulwazi oluningi oluchwepheshile luzokwabelwana nawe ukuze likusize wenze ibhizinisi kangcono namakhasimende.