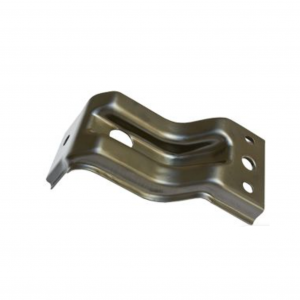

Isitembu sezingxenye zensimbi ze-aluminium

Incazelo

| Uhlobo Lomkhiqizo | umkhiqizo ngokwezifiso | |||||||||||

| Isevisi ye-One-Stop | Ukuthuthukiswa kwesikhunta kanye nomklamo-hambisa amasampuli-inqwaba yokukhiqiza-ukuhlola-ukwelashwa-ukupakisha-ukulethwa. | |||||||||||

| Inqubo | ukunyathela, ukugoba, ukudweba okujulile, ukwakhiwa kwensimbi yeshidi, ukushisela, ukusika i-laser njll. | |||||||||||

| Izinto zokwakha | carbon steel, insimbi engagqwali, i-aluminium, ithusi, insimbi yashukumisa njll. | |||||||||||

| Ubukhulu | ngokuya ngemidwebo yekhasimende noma amasampula. | |||||||||||

| Qeda | Futha umdwebo, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njll. | |||||||||||

| Indawo Yesicelo | Izingxenye zezimoto, izingxenye zemishini yezolimo, izingxenye zemishini yobunjiniyela, izingxenye zobunjiniyela bokwakha, izesekeli zengadi, izingxenye zemishini ezivumelana nemvelo, izingxenye zomkhumbi, izingxenye zezindiza, ukufakwa kwamapayipi, izingxenye zamathuluzi ehadiwe, izingxenye zamathoyizi, izingxenye ze-elekthronikhi, njll. | |||||||||||

Izinzuzo

1. Ngaphezu kweminyaka eyi-10yobungcweti bokuhwebelana phesheya kwezilwandle.

2. Nikezaisevisi eyodwa-stopkusukela ekwakhiweni kwesikhunta kuya ekulethweni komkhiqizo.

3. Isikhathi sokulethwa okusheshayo, cisheIzinsuku ezingama-30-40. Isitoko lingakapheli iviki elilodwa.

4. Ukuphathwa kwekhwalithi okuqinile kanye nokulawulwa kwenqubo (ISOUmkhiqizi oqinisekisiwe kanye nemboni).

5. Amanani anengqondo ngaphezulu.

6. Professional, imboni yethu ineezingaphezu kuka-10iminyaka yomlando emkhakheni wensimbi yokugxiviza ishidi lensimbi.

Ukuphathwa kwekhwalithi

Ithuluzi lokuqina likaVickers.

Ithuluzi lokulinganisa iphrofayela.

Insimbi ye-Spectrograph.

Ithuluzi lokuxhumanisa ezintathu.

Isithombe Sokuthunyelwa

Inqubo Yokukhiqiza

01. Isikhunta design

02. Ukucutshungulwa Kwesikhunta

03. Ukucubungula ucingo

04. Ukwelashwa kokushisa kwesikhunta

05. Ukuhlanganiswa kwesikhunta

06. Ukulungisa iphutha lesikhunta

07. Ukukhipha imali

08. i-electroplating

09. Ukuhlolwa Komkhiqizo

10. Iphakheji

Iphrofayela Yenkampani

Njengomunye wabaphakeli abahamba phambili baseShayina bensimbi enesitembu esigxiviziwe, i-Ningbo Xinzhe Metal Products Co., Ltd. igxile ekukhiqizeni izingxenye zezimoto, izingxenye zemishini yezolimo, izingxenye zobunjiniyela, izingxenye zobunjiniyela bokwakha, izesekeli zehadiwe, izingxenye zemishini ezinobungani bemvelo, izingxenye zomkhumbi, izingxenye zezindiza, okokufakwa kwamapayipi, amathuluzi ehadiwe, amathoyizi, nezinsiza zikagesi, phakathi kwezinye izinto.

Zombili izinhlangothi ziyazuza ekhonweni lethu lokuqonda ngokugcwele imakethe eqondiwe futhi zinikeze izincomo ezisebenzayo ezizosiza amakhasimende ethu ukuthi athole isabelo semakethe esikhulu. Sizinikele ekunikezeni amakhasimende ethu isevisi evelele nezingxenye ze-premium ukuze sizuze ukwethenjwa kwawo. Sungula ukuxhumana okuhlala njalo namakhasimende amanje futhi uphishekele ibhizinisi elisha emazweni angewona ozakwethu ukuze ukhuthaze ukubambisana.

Inqubo ye-oxidation

Izinyathelo ezilandelayo zivame ukufakwa kunqubo ye-oxidation:

1. Ukuphakelwa kwempahla eluhlaza: Sebenzisa amapayipi ukuhlinzeka ngezinto ezingavuthiwe kwireactor ukuze ugcine ibhalansi efanele yezinto ezingavuthiwe ngaphakathi.

2. Ukusabela: Ukuze wenze ukusabela kwe-oxidation, engeza umoya-mpilo kwi-reactor futhi ulawule imingcele yokusabela (njengezinga lokushisa, ukucindezela, nesikhathi sokusabela).

3. Ukuhlukaniswa komkhiqizo: Sebenzisa isibandisi somoya ukupholisa umkhiqizo ophenduliwe, uwuguqule usuke esimweni segesi uwenze uketshezi noma oqinile, bese usebenzisa isihlukanisi ukuze uhlukanise imikhiqizo evela ezingxenyeni ezihlukahlukene.

4. Ukuhlanzwa: Ukuqinisekisa ukuthi umkhiqizo wokusabela ufinyelela ubumsulwa obudingekayo, uwuhlanze.

5. Ukupakishwa: Ngemva kokuba imikhiqizo isihlanziwe, iyapakishwa ngokuvumelana neziqondiso namazinga ngaphambi kokuthi ithengiswe kumakhasimende noma ithunyelwe esigabeni esilandelayo sokucutshungulwa.

Kwezinye izinhlelo zokusebenza ezithile, ezifana nokucutshungulwa kwe-wafer ye-semiconductor, inqubo ye-oxidation iphinde ihlanganise nokuhlinzeka ngama-oxidants (njengamanzi, umoya-mpilo) namandla ashisayo ku-silicon substrate ukuze kwakhe ifilimu ye-silicon dioxide (SiO2). Le filimu ye-oxide ivikela i-wafer ngokuvimbela ukuvuza kwamanje ukuthi ingagelezi phakathi kwamasekhethi, ivimbele ukusakazeka phakathi nenqubo yokufaka i-ion, futhi isebenze njengefilimu evimbela ukuhushulwa evimbela ukufakwa okuyiphutha phakathi nenqubo yokuhlanganisa.