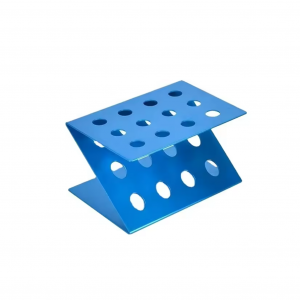

Insimbi eyenziwe ngokwezifiso ye-laser egoba izingxenye zokwenziwa kwensimbi ye-Carbon steel sheet

Incazelo

| Uhlobo Lomkhiqizo | umkhiqizo ngokwezifiso | |||||||||||

| Isevisi ye-One-Stop | Ukuthuthukiswa kwesikhunta kanye nomklamo-hambisa amasampuli-inqwaba yokukhiqiza-ukuhlola-ukwelashwa-ukupakisha-ukulethwa. | |||||||||||

| Inqubo | ukunyathela, ukugoba, ukudweba okujulile, ukwakhiwa kwensimbi yeshidi, ukushisela, ukusika i-laser njll. | |||||||||||

| Izinto zokwakha | carbon steel, insimbi engagqwali, i-aluminium, ithusi, insimbi yashukumisa njll. | |||||||||||

| Ubukhulu | ngokuya ngemidwebo yekhasimende noma amasampula. | |||||||||||

| Qeda | Futha umdwebo, i-electroplating, i-hot-dip galvanizing, i-powder coating, i-electrophoresis, i-anodizing, i-blackening, njll. | |||||||||||

| Indawo Yesicelo | Izingxenye zezimoto, izingxenye zemishini yezolimo, izingxenye zemishini yobunjiniyela, izingxenye zobunjiniyela bokwakha, izesekeli zengadi, izingxenye zemishini ezivumelana nemvelo, izingxenye zomkhumbi, izingxenye zezindiza, ukufakwa kwamapayipi, izingxenye zamathuluzi ehadiwe, izingxenye zamathoyizi, izingxenye zikagesi, njll. | |||||||||||

Izitembu eziyisisekelo

Ukugxiviza (okubuye kubizwe ngokuthi ukucindezela) kuhlanganisa ukubeka insimbi eyisicaba kukhoyili noma ngendlela engenalutho emshinini wokugxiviza.Emshinini wokunyathelisa, ithuluzi kanye nezindawo ezifayo zibumba insimbi ibe yijamo oyifunayo.Ukubhoboza, ukuvala, ukugoba, ukunyathela, ukufaka embossing kanye ne-flanging yiwo wonke amasu okugxiviza asetshenziselwa ukubumba insimbi.

Ngaphambi kokuthi kwakhiwe impahla, ochwepheshe bokugxiviza kufanele baklame isikhunta ngobunjiniyela be-CAD/CAM.Le miklamo kufanele icace ngangokunokwenzeka ukuze kuqinisekiswe imvume efanele yesibhakela ngasinye kanye nokugoba ngekhwalithi yengxenye efanelekile.Imodeli ye-3D yethuluzi elilodwa ingaqukatha amakhulu ezingxenye, ngakho-ke inqubo yokuklama ivamise ukuba yinkimbinkimbi futhi idla isikhathi.

Uma umklamo wethuluzi usunqunyiwe, abakhiqizi bangasebenzisa izinhlobonhlobo zomshini, ukugaya, ukusika izintambo, nezinye izinsizakalo zokukhiqiza ukuze baqedele ukukhiqizwa kwalo.

Ukuphathwa kwekhwalithi

Ithuluzi lokuqina likaVickers.

Ithuluzi lokulinganisa iphrofayela.

Insimbi ye-Spectrograph.

Ithuluzi lokuxhumanisa ezintathu.

Isithombe Sokuthunyelwa

Inqubo Yokukhiqiza

01. Isikhunta design

02. Ukucutshungulwa Kwesikhunta

03. Ukucubungula ucingo

04. Ukwelashwa kokushisa kwesikhunta

05. Ukuhlanganiswa kwesikhunta

06. Ukulungisa iphutha lesikhunta

07. Ukukhipha imali

08. i-electroplating

09. Ukuhlolwa Komkhiqizo

10. Iphakheji

Izinhlobo zokugxiviza

Sinikezela ngesiteji esisodwa nesiningi, i-progressive die, i-deep draw, i-fourslide, nezinye izindlela zokugxiviza ukuze uqinisekise indlela ephumelela kakhulu yokukhiqiza imikhiqizo yakho.Ochwepheshe be-Xinzhe bangafanisa iphrojekthi yakho nesigxivizo esifanele ngokubuyekeza imodeli yakho ye-3D elayishiwe kanye nemidwebo yobuchwepheshe.

- I-Progressive Die Stamping isebenzisa ama-dies amaningi nezinyathelo ukudala izingxenye ezijulile kunalokho obekungafinyelelwa kuzo ngokufa okukodwa.Iphinde inike amandla amajiyometri amaningi ingxenye ngayinye njengoba edlula ekufa okuhlukahlukene.Le nqubo ifaneleka kakhulu umthamo ophezulu kanye nezingxenye ezinkulu njengalezo ezisembonini yezimoto.I-Transfer die stamping iyinqubo efanayo, ngaphandle kokuthi isitembu sokufa esiqhubekayo sihlanganisa ucezu lokusebenza olunamathiselwe emgqeni wensimbi odonswe kuyo yonke inqubo.I-Transfer die stamping isusa ucezu lokusebenza futhi iluhambise eduze kwe-conveyor.

- I-Deep Draw Stamping idala izitembu ezinemigodi ejulile, njengonxande abavalelwe.Le nqubo idala izingcezu eziqinile kusukela ukuwohloka okwedlulele kwensimbi kucindezela isakhiwo sayo sibe ifomu elicwebezelayo.Ukugxiviza okujwayelekile kokudweba, okubandakanya ukufa okungajulile okusetshenziselwa ukubumba insimbi, nakho kuvame ukusetshenziswa.

- I-Fourslide Stamping ibumba izingxenye ukusuka kuzimbazo ezine esikhundleni sokusuka ohlangothini olulodwa.Le ndlela isetshenziselwa ukwakha izingxenye ezincane eziyinkimbinkimbi ezihlanganisa izingxenye ze-electronics njengezixhumi zebhethri yefoni.Inikeza ukuguquguquka okwengeziwe kwedizayini, izindleko eziphansi zokukhiqiza, kanye nezikhathi zokukhiqiza ezisheshayo, isitembu se-fourslide sidumile ezimbonini ze-aerospace, zezokwelapha, zezimoto, nezikagesi.

- I-Hydroforming iyinguquko yokugxiviza.Amashidi abekwe phezu kwedayizi enomumo ophansi, kuyilapho ukwakheka okungaphezulu kuyisinye sikawoyela esigcwala ukucindezela okuphezulu, ukucindezela insimbi ibe sesimweni sefa elingezansi.Izingxenye eziningi zingakhiwa nge-hydroform ngesikhathi esisodwa.I-Hydroforming iyindlela esheshayo nenembayo, nakuba idinga ukusika izingxenye zeshidi ngemva kwalokho.

- Ukuvala kusika izingcezu eshidini njengesinyathelo sokuqala ngaphambi kokwenza.I-Fineblanking, inguquko yokungasho lutho, yenza ukusikeka okunembile ngemiphetho ebushelelezi kanye nendawo eyisicaba.

- I-Coining ingolunye uhlobo lokuvala okudala ama-workpieces amancane ayindilinga.Njengoba kuhilela amandla abalulekile ukwakha ucezu oluncane, kwenza insimbi ibe lukhuni futhi isuse ama-burrs namachopho amaholo.

- Ukushaya ngesibhakela kuphambene nokuvala;kuhilela ukususa impahla ku-workpiece esikhundleni sokususa izinto ukuze udale i-workpiece.

- I-embossing idala idizayini enezinhlangothi ezintathu ensimbi, ephakanyiswe ngaphezu kwendawo noma ngochungechunge lwezingcindezi.

- Ukugoba kwenzeka ku-eksisi eyodwa futhi kuvame ukusetshenziselwa ukwakha amaphrofayili ngomumo ongu-U, V, noma u-L.Le nqubo yenziwa ngokugoqa uhlangothi olulodwa bese ugoba olunye phezu kwedayizi noma ngokucindezela insimbi ibe yifa noma imelene nayo.I-Flanging igobela amathebhu noma izingxenye zocezu lokusebenza esikhundleni sayo yonke ingxenye.

Ukubekezelelana okuqinile

Noma ngabe usembonini ye-aerospace, yezimoto, yezokuxhumana noma ye-elekthronikhi, izinsiza zethu zokugxiviza izitembu zensimbi ezinembayo zingaletha izingxenye zomumo ozidingayo.Abahlinzeki bethu basebenza kanzima ukuze bahlangabezane nezidingo zakho zokubekezelela ngokuphindaphinda ithuluzi kanye nemiklamo yesikhunta ukuze ulungise okukhiphayo ukuze uhlangabezane nezidingo zakho.Nokho, lapho ukubekezelelana kuqina, kuba nzima nakakhulu futhi kubiza.Izitembu zensimbi ezinembile ezinokubekezelela okuqinile kungaba abakaki, iziqeshana, okufakwayo, izixhumi, izesekeli nezinye izingxenye ezinsizeni zabathengi, amagridi kagesi, izindiza nezimoto.Ziphinde zisetshenziselwe ukwenza izimila, amathuluzi okuhlinza, ama-temperature probe nezinye izingxenye zemishini yezokwelapha njengezindlu nezingxenye zephampu.

Ukuhlola okuvamile ngemva kokugijima ngakunye okulandelanayo ukuqinisekisa ukuthi okukhiphayo kusengaphakathi kokucaciswa kuvamile kuzo zonke izitembu.Ikhwalithi nokungaguquguquki kuyingxenye yohlelo oluphelele lokulungiswa kokukhiqiza oluqapha ukuguga kwamathuluzi.Izilinganiso zisebenzisa amajigi okuhlola ziyizilinganiso ezijwayelekile emigqeni yokugxiviza edonsa isikhathi eside.